EME Dipmaster

Stainless steel machine for filling products that are difficult to fill, such as strips and shredded products as well as many other salad and mixed products

Description

The EME DIPMASTER is a special filling machine for products that are very difficult to fill, such as strips and grated products as well as many other salad and mixed products. The products must be pumpable, as water or infusion liquid is used as the conveying medium.

Function

The machine operates in continuous rotation with up to 24 filling stations. The product is fed into the built-in suction vessel and sucked in by lowering the dosing elements. The desired volume can be infinitely adjusted via central adjustment. The setting can also be made during the rotation.

The product sucked into the dosing chamber is separated from the conveying medium and transferred via counter pistons that are immersed in the containers to be filled. While the product is sucked in on one side of the machine, the containers pass through the other side for the filling process.

The infeed starwheel continuously allocates the jars or cans to the filling stations. The containers are fed through the machine via a curved track. The machine stops automatically if no packs are fed in.

Performance range:

- up to 250 containers per minute

Special features:

- The filling system is a combination of volumetric, piston and vacuum filler

Various additional options available!

Examples of Dipmaster filling machines for the food industry

Technical data

Performance:

(depending on filling quantity and product):

150 – approx. 250 fillings/min

Container size:

with the use of appropriate

Interchangeable cylinders from 200ml – 850l

Connected loads:

Electrical connection: 400V; 50 Hz; approx. 30 kW incl. pumps

Pneumatic connection: R 1/4″; 6 bar

Liquid consumption max. 3.6 m³/h

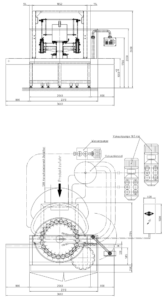

Installation plan:

Advantages of our Dipmaster filling machine

For particularly gentle food filling

Special customer requirements can be addressed during the entire design phase.

Available in any desired size.