EME cabbage filling machine SCHUME

Stainless steel machine for direct filling of cabbage

Description

EME SCHUME high-performance filling machines are suitable for almost all cut or fibrous vegetable products.

Sauerkraut, red cabbage, vegetable salads or kale can be filled in raw or blanched condition particularly quickly, gently and with a high yield.

Function

The EME SCHUME operates in continuous rotary mode and is equipped with four stations. It fills cans and jars directly, without the product having to be pressed around several corners.

A specially tested feed screw with infinitely variable drive conveys the product directly to the machine’s filling station.

The desired dosed quantity is automatically cut off and then pushed slowly and evenly through the upper piston into the can or jar. The plunger dips into the can/jar to such an extent that a finished headspace is created at the same time. The cans/jars leave the machine ready to be capped and do not need to be repacked.

The cans/jars are fed in via the attached conveyor belt. The infeed starwheel feeds the cans/jars into the machine and at the outfeed, the cans/jars are moved back onto the belt by the backlog.

The machine’s output is infinitely variable. The integrated automatic switch prevents underfilling. The machine stops automatically if the intended dosing quantity has not yet been reached.

Examples of haulm filling machines

Available types of SCHUME haulm filling machine

| Type | Capacity in fillings / min |

|---|---|

| SCHUME 5 | up to 6 at 25 kg |

| SCHUME 6 | up to 15 for 10/1 |

| SCHUME 10 | up to 35 at 5/1 |

| SCHUME 12 | up to 100 |

| SCHUME 18 | up to 150 |

| SCHUME 24 | up to 240 |

| SCHUME 32 | up to 380 |

| SCHUME 40 | up to 500 |

Further details

Performance:

(depending on filling quantity and product):

50 – approx. 100 fillings/min

Container size:

depending on machine design and

corresponding exchangeable cylinder

Connected loads:

Electr. Connection: 400V; 50 Hz; approx. 4 kW

Pneumatic connection: R 1/4″; 6 bar

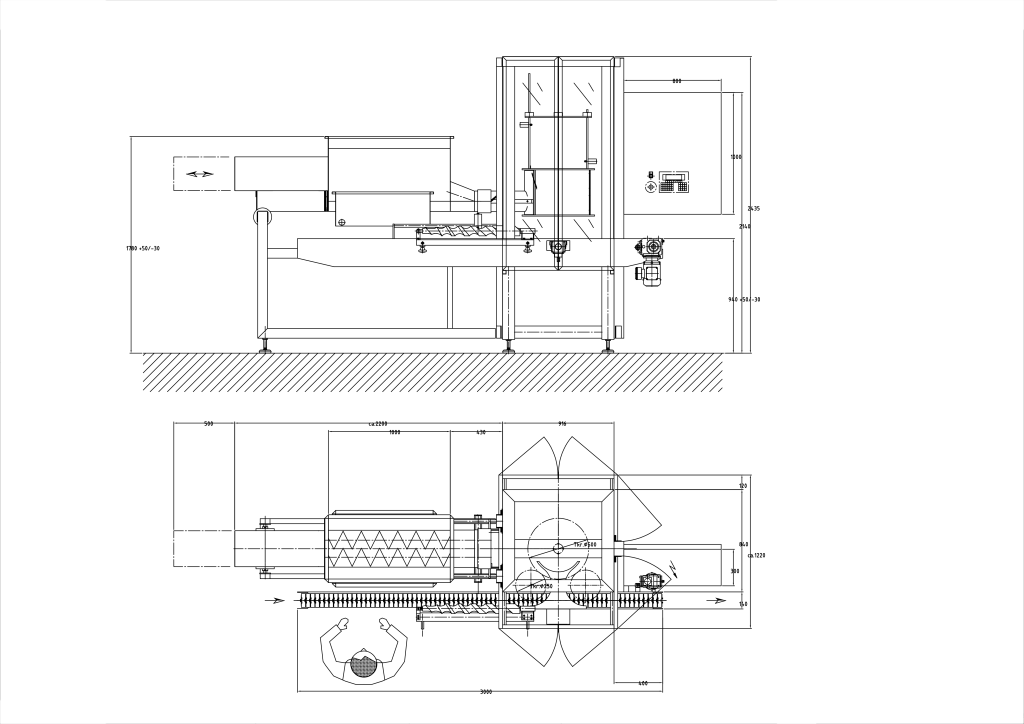

Installation plan:

We supply customized haulm filling machines

Direct filling without having to press the product around several corners.

Special customer requirements can be addressed during the entire design phase.

Available in any desired size.