EME vacuum filling machine

Machine for infusing a wide range of products

Description

The EME vacuum filling machine is equipped with 6 to 50 filling stations and is suitable for filling a wide variety of products.

Function

The containers to be filled are continuously assigned to the individual filling stations via a slat conveyor and a feed screw as well as an infeed starwheel. A lifting plate is located under each filling station, which lifts the jars/cans via a forced curve and presses them against the filling head.

Glass height tolerances of up to 5 mm are automatically compensated for by the lifting plate. When the container is lifted, the newly designed lifting filling head is moved upwards over the jar/can to initiate the switching processes for vacuum, filling and venting.

It is controlled via smoothly moving cam segments in which the switching rods are moved and thus actuate the filling valve. By using several cam segments, double switching is also possible. The valve is only activated when a container is positioned under the filling head. This means that no filling takes place without a jar/can.

Once the filling process is complete, the lifting plate lowers again and transfers the filled jars/cans tangentially to the seaming machine belt.

The machine is equipped with a central height adjustment of the entire machine head including program switching cam. Changeover times can therefore be drastically reduced and limited to the replacement of interchangeable parts. The height adjustment to a different glass height is carried out via a gear motor at the touch of a button.

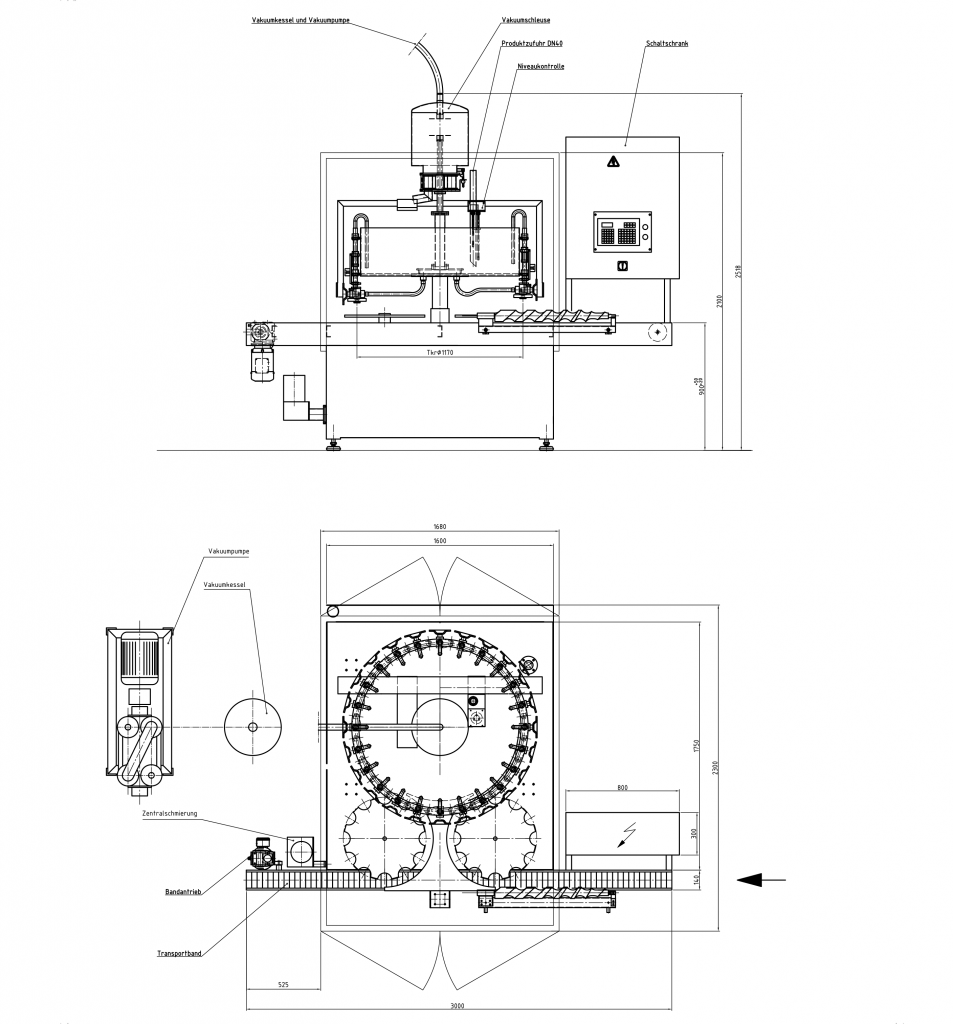

Pictures of vacuum filling machines

Available types of EME vacuum filling machines

| Type | Capacity in fillings / min | Pitch circle |

|---|---|---|

| V 4 | up to 60 | 540 |

| V 6 | up to 80 | 540 |

| V 8 | up to 100 | 540 |

| V 10 | up to 140 | 540 |

| V 12 | up to 170 | 750 |

| V 15 | up to 210 | 750 |

| V 18 | up to 250 | 880 |

| V 20 | up to 280 | 1170 |

| V 24 | up to 340 | 1170 |

| V 27 | up to 380 | 1310 |

| V 30 | up to 420 | 1310 |

| V 32 | up to 450 | 1610 |

| V 36 | up to 500 | 1610 |

| V 40 | up to 560 | 1950 |

| V 44 | up to 620 | 1950 |

| V 50 | up to 700 | 2200 |

Further details

Performance:

(depending on filling quantity and product):

up to approx. 340 fillings/min

Container size:

when using appropriate format parts

and interchangeable cylinders from 20ml – 10l

Connected loads:

Electr. Connection: 400V; 50 Hz; approx. 10 kW

Pneumatic connection: R 1/4″; 6 bar

Product feed DN40

Installation plan:

Benefit from customized vacuum filling machines

Short product paths, as the valves are mounted directly on the filling container

Easy to clean as no moving parts, such as switching rods, protrude into the product container.

Good accessibility to the valve control unit.