EME volumetric filling machines

Machines for filling lumpy and pourable products

Description

EME volumetric dosing fillers are specially designed for chunky and pourable products in the canning and frozen food industry. Various foodstuffs such as fruit, vegetables, rice, pasta, mixed products or pieces of meat are suitable for filling.

The filling volume is determined by infinitely adjustable dosing chambers in the filling machine.

EME volumetric dosing fillers are equally suitable for partial dosing as well as full filling of individual components in cans, jars and folding cartons.

Function

This machine works in continuous rotation and is equipped with up to 60 filling stations. Each filling station consists of a telescopic cylinder with a bottom-mounted rotary slide. This slide only opens when a can/jar is under the filling station. This means that no can/jar = no filling.

The entire filling table is electrically height-adjustable via the central column. All filling cylinders are telescopically extended and retracted at the same time. In this way, it is possible to increase the dosing volume up to twice as much and even more by inserting intermediate pieces.

The use of interchangeable format parts makes it possible to switch to a different can, jar or bottle size at short notice. The dosing range can be further increased by using additional dosing tube sets.

Performance range:

- up to 500 containers per minute

Special features:

- Sturdy base frame in stainless steel welded construction, machine table designed as a drip tray.

Various additional options available!

Examples of volumetric dosing

filling machines

Available types of our

Volumetric dosing

filling machines

| Type | Capacity in fillings / min | Pitch circle |

|---|---|---|

| DOS 6 | up to 70 | 540 |

| DOS 10 | up to 130 | 540 |

| DOS 12 | up to 150 | 750 |

| DOS 15 | up to 190 | 750 |

| DOS 18 | up to 230 | 880 |

| DOS 24 | up to 300 | 1170 |

| DOS 27 | up to 340 | 1310 |

| DOS 32 | up to 400 | 1610 |

| DOS 36 | up to 450 | 1610 |

| DOS 40 | up to 500 | 1950 |

| DOS 44 | up to 550 | 1950 |

| DOS 50 | up to 620 | 2200 |

| DOS 12/8 | up to 30 | 750 |

Technical data

Performance:

(depending on filling quantity and product):

15 – approx. 230 fillings/min

Container size:

depending on machine design and

corresponding dosing chamber from 20ml – 10l

Connected loads:

Electr. Connection: 400V; 50 Hz; up to approx. 1.7 kW

Pneumatic connection: R 1/4″; 6 bar

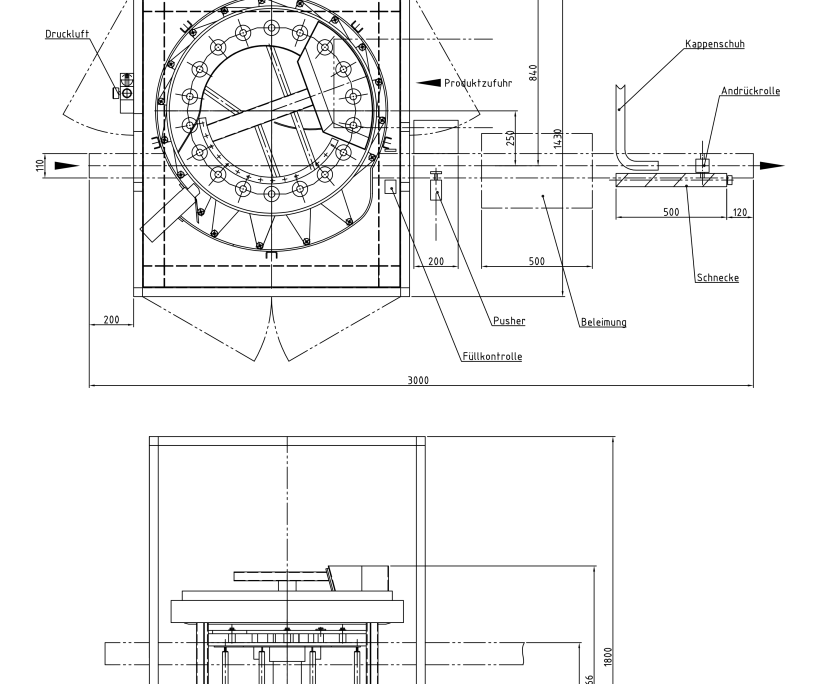

Installation plan:

Advantages of our volumetric dosing

filling machines

Each machine is individually adapted to your product

Special customer requirements can be addressed during the entire design phase.

Available in any desired size.