EME Skinning machine Supra E-10

Machine for de-stemming or peeling food

Description

The EME SUPRA E-10 de-stemming and destemming machine was developed for the gentle processing of cherries, mirabelles, plums and various types of berries, for example, as well as for peeling silver onions, skinning almonds or removing petals from gherkins.

Function

The product is fed either manually, via a feed elevator, feed belt or a vibrating chute. The fruit enters the working area of the counter-rotating rollers via the infeed hopper at the rear. The rollers, which are guided in special plastic bearings, pick up stalks, leaves and peel as well as foreign bodies and discharge them downwards through the roller bed.

A turning carriage with rubber distributors mounted above the roller bed ensures that the fruit is distributed very gently and evenly, whereby it is turned several times and any protruding stalks, leaves, etc. reach the effective area of the rollers. Spray pipes mounted on the turning carriage are used for intensive cleaning of the product and simultaneous cooling of the special bearings. The de-stemmed and washed product rolls unhindered on the inclined roller bed to the machine outlet.

Structure

The base frame consists of a sturdy stainless steel cantilever frame, which allows free access underneath the discharge area. The stainless steel rollers, which rotate against each other, are covered with rubber and mounted in special plastic bearings with deflection springs. The 50 rollers are driven on one side by a special stainless steel gearbox mounted underneath the feed hopper. The water-cooled gearbox is completely enclosed and therefore maintenance-free. Damaged rollers can be replaced quickly and easily thanks to special plug-in adapters and special plastic bearings.

Longer downtimes and production interruptions are therefore virtually eliminated. The inclination of the roller bed can be infinitely adjusted depending on the raw material. The machine bed is also freely accessible.

Conveyor equipment for the product feed, sorting belts at the machine outlet and belts for removing stalk waste are easy to fit.

The machine is a completely new design from EME with many technical advantages, such as

- one-sided drive of all 50 plucking rollers

- Unhindered product flow at the ends of the rollers

- Divided plastic bearings with soft suspension

- closed oil bath gearbox stainless

- Quick replacement of individual plucking rollers

- Encapsulated drive motor with weight tensioner for V-belts

- Reversing device with overload protection

- Infinitely variable tilt angle adjustment via spindle and handwheel

- Free access underneath the discharge area

- Excellent running smoothness

Picture gallery

Further details

Performance:

Depending on the product from 0.6 to approx. 2.0 tons / hour

Various additional options available!

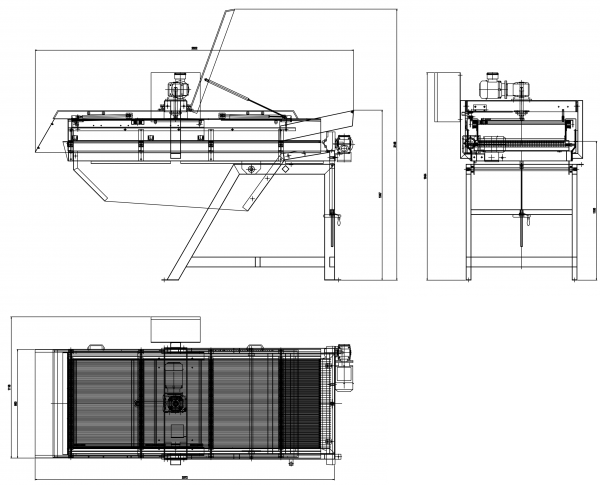

Installation plan:

Advantages of EME de-stemming machines

Direct filling without having to press the product around several corners.

Special customer requirements can be addressed during the entire design phase.

Available in any desired size.