EME RF Compact with multihead weigher

Machine for the industrial filling of lumpy and pourable products

Description

This machine operates in continuous rotation and is equipped with up to 20 filling stations. Each filling station consists of a filling hopper with dosing tube, which receives the pre-weighed product from the multihead weigher. The dosing tube is open at the bottom so that the can, jar or folding carton below is filled directly after discharge.

The packs pass through a vibrating section during the rotary process so that the product that is still protruding is vibrated into the pack. The dosing tubes, which are positioned directly above the packs, prevent the product from falling out during the filling process.

The filled packs are transferred via a discharge starwheel for further transportation. The empty packs are fed to the machine via the attached conveyor belt, infeed auger and starwheel. The packs are guided during the cycle via the central starwheel and outer railing.

Function

Design: stable base frame in stainless steel welded construction, machine table designed as a drip tray.

Drive: frequency-controlled with stainless steel safety clutch.

Electr. Equipment: Machine completely wired, control and operating panel with all switches and contactors on console. Operating side on the infeed plate conveyor.

The machine is electrically synchronized with an existing multihead weigher to ensure smooth product transfer. The dosing chamber and the containers are only filled when a container is ready for filling. This is ensured by a jam switch at the inlet of the machine.

Pictures of Kompakter special machines

Available types of EME Compact

| Type | Capacity in fillings / min |

|---|---|

| RF 1 | up to 35 |

| RF 12/6 | up to 80 |

| RF 18/8 | up to 110 |

| RF 20/10 | up to 140 |

| RF 27/14 | up to 200 |

| RF 32/16 | up to 230 |

| RF 40/20 | up to 290 |

| RF 50/30 | up to 380 |

Further details

Performance:

(depending on filling quantity and product):

up to approx. 80 fillings/min

Connected loads:

Electr. Connection: 400V; 50 Hz; approx. 5 kW

Pneumatic connection: R 1/4″; 6 bar

Air consumption max. 670 l/h

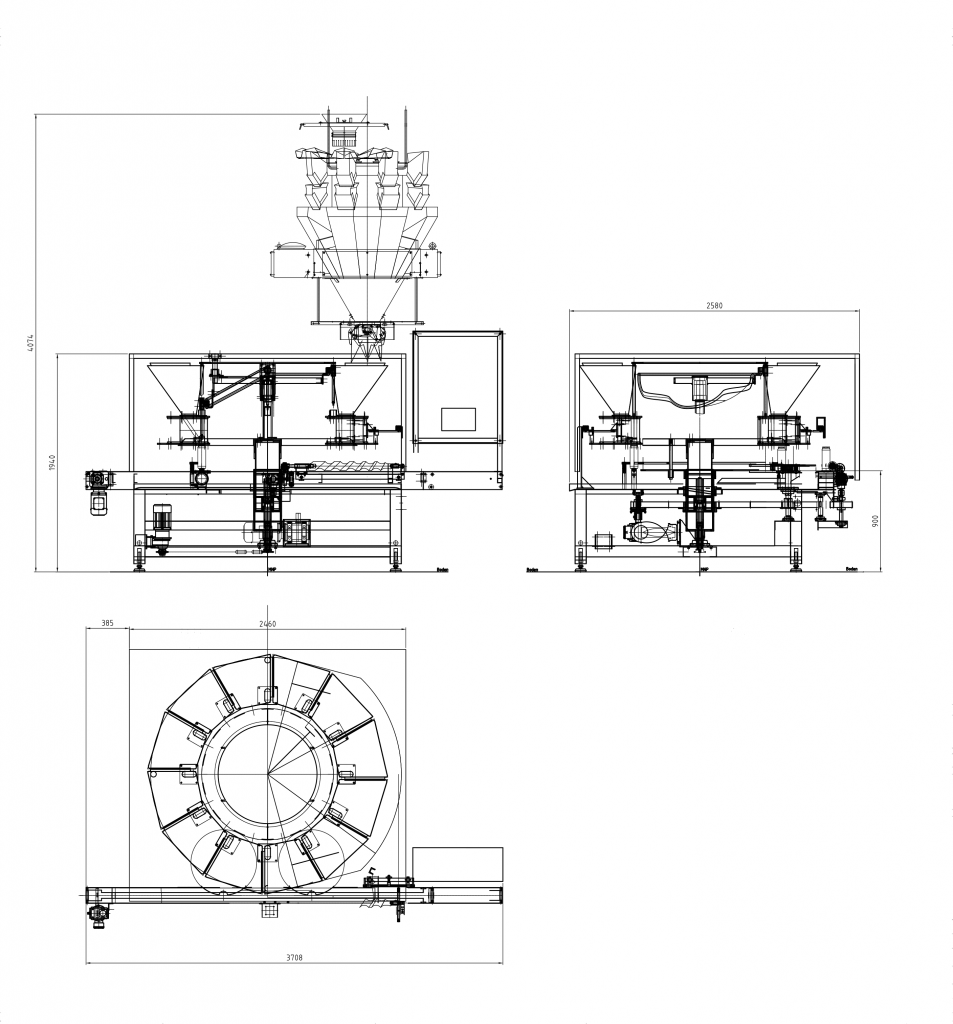

Installation plan:

Advantages of compact with multihead weigher

High filling accuracy

Easy to clean as no moving parts, such as switching rods, protrude into the product container.

Good accessibility to the valve control unit.