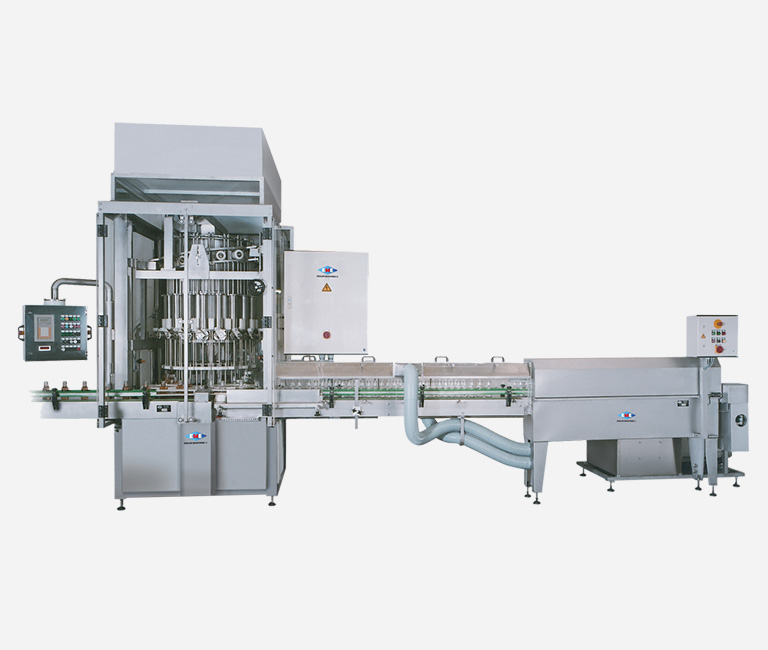

EME piston filling machines

Machines for filling thin, thick and pasty products

Description

Piston filling machines are especially suitable for filling thin, thick and pasty products. They can be used for partial or full filling (cold or hot filling) into cans, jars and bottles.

Function

Piston filling machines operate in continuous rotation and can be equipped with up to 36 filling stations, depending on the desired output range.

The use of interchangeable format parts makes it possible to switch to a different can, jar or bottle size at short notice. The dosing range can be further increased by using interchangeable cylinders.

Examples of piston filling machines

Available types of piston filling machines

| Type | Capacity in fillings / min | Pitch circle |

|---|---|---|

| K 4 | up to 70 | 540 |

| K 6 | up to 90 | 540 |

| K 8 | up to 120 | 540 |

| K 10 | up to 150 | 540 |

| K 12 | up to 180 | 750 |

| K 15 | up to 225 | 750 |

| K 18 | up to 270 | 880 |

| K 20 | up to 300 | 1170 |

| K 24 | up to 360 | 1170 |

| K 27 | up to 410 | 1310 |

| K 32 | up to 480 | 1610 |

| K 36 | up to 540 | 1610 |

| K 12/6 | up to 25 (5/1) | 750 |

| K 12/9 | up to 37 (5/1) | 750 |

| K 18/8 | to 33 (5/1) | 880 |

| K 20/12 | up to 55 (5/1) | 1170 |

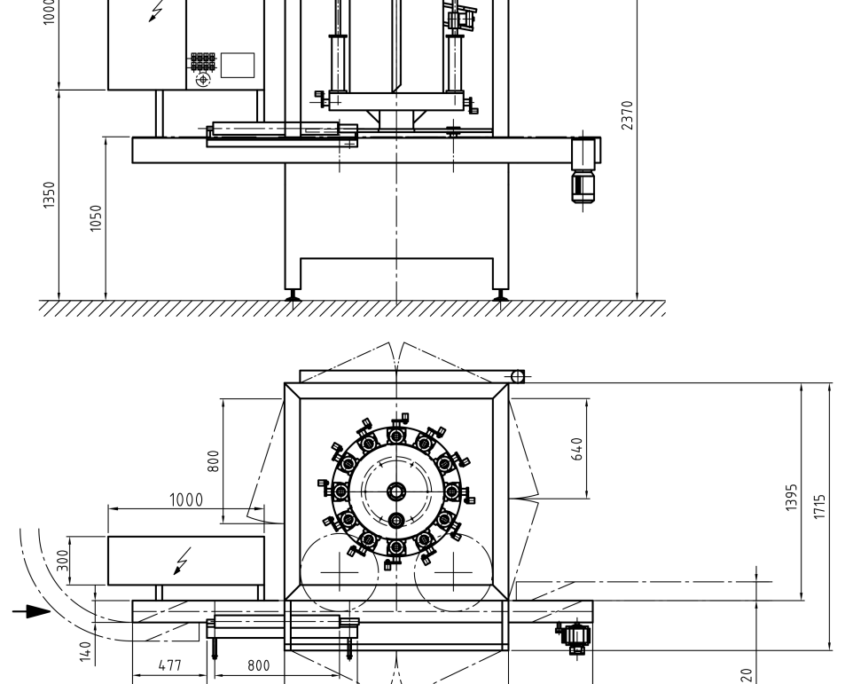

Technical data

Performance:

(depending on filling quantity and product):

50 – approx. 100 fillings/min

Container size:

when using appropriate format parts

and interchangeable cylinders from 20ml – 10l

Connected loads:

Electrical connection: 400V; 50 Hz; approx. 2.5 kW

Pneumatic connection: R 1/4″; 6 bar

Air consumption max. 120 l/h

Product feed DN40

Installation plan:

Advantages of a piston filling machine

Direct filling without having to press the product around several corners.

Special customer requirements can be addressed during the entire design phase.

Available in any desired size.